Where: Large Automotive OEM, ASIA

Challenge:

- 400 parts suppliers, each following their own quality control plans instead of the OEM’s.

- Supplier inspection checks were subjective – no traceability & prone to errors.

- OEM had to perform post-delivery checks which yielded high number of defects – expensive and production-impacting.

BorgConnect® Solution:

- Real-time integration of OEM-supplier QA processes,

- OEM remote visibility,

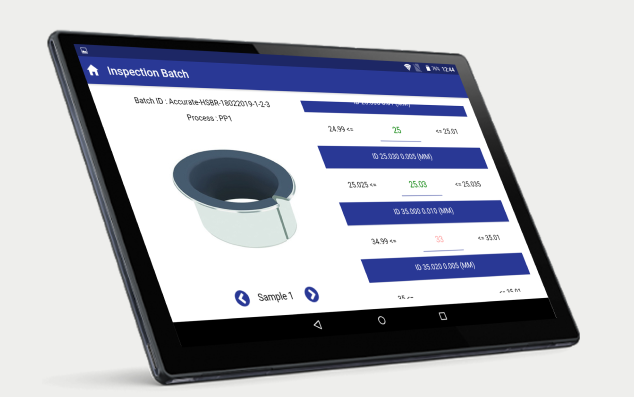

- Digital measurement instruments and a tablet app that digitized supplier checks while flagging non-conformance to OEM standards.

Results:

- OEM achieved zero defective parts per million within 3 months.

- OEM’s concurrent remote visibility eliminated post-delivery checks (non-value-added activity) & enabled a true picture of quality.

- Digitalization at suppliers led to improve labour productivity, training, and quality practices.